PRODUCTSProduct Information

Life science automation products

Mechatro CO₂ Incubator SCALE48

Product Features

“Mechatro CO2 Incubator SCALE48” is an incubator mounted transfer robot. It powerfully supports cell culture automatization using ”AsuRa®” (comprehensive scheduling software package for bio automation).

- The dry heat sterilization function using direct dry heating is equipped with as standard

- High reliability is realized by complete isolation of electrical components and drive systems from inside

- Stable culture for up to 48 plates is performed adopting a carousel type turntable

- Removing the turntable makes the inside completely flat and easy to clean

- Change in the internal environment at time of plate loading in and out is reduced using the shutter method

Main specifications common to all mode (option)

- Low oxygen culture O2 concentration lower than 1%

- Access -stage transport height- 300 mm ~ 900 mm above the floor (note:580~980mm is unable to be set)

- Bracket for fixing equipment

- Double pitch

- Front loading

- Circulation system

- Hydrogen peroxide option

- Barcode

Specifications (Standard SCALE48)

- Transportable item

-

φ100mm dish + transport attachment plate(note: up to total 26mm height)

φ60mm dish+ transport attachment plate(note: up to total 26mm height)

SBS standard micro plate (note: up to total 26mm height) - Temperature

-

-during culture- 37±0.5℃

-during sterilization- higher than 125℃ (5 consecutive hours heating) - CO2 concentration

- 50.5%

- Power

- Single phase AC 100V15A

- Gas(CO2)

-

Flow rate 5L/min

Pressure 0.2MPa - Size

- W620xD953xH1060

- Volume

- 125L (48 plates loadable)

- Weight

- 230kg

- Safety function

-

-Process interlock-

-Door lock during sterilization

-When the door is open, the turning table, the action of transfer robot and the supply of CO2 / N2 are temporarily stopped. The operation continues after the door is closed. When the robot detects a load in the rack, an error is displayed to prevent double loading, and the plate is returned to the delivery stage.

-Internal environment interlock-

-During power outage, CO2 / N2 supply is cut off.

-Sterilization interlock-

-The door lock during sterilization is not released until the inside temperature falls below the culture temperature. (If sterilization is stopped, it is not released until the temperature drops below 55℃)

Specifications (Z extension model, SCALE48ZE)

SCALE48 standard specifications + extended Robot Z-axis

Specifications (SCALE48RM)

SCALE48 standard specifications + Stainless steel cover specification + Hydrogen peroxide decontamination cover included

Specifications (Z extension SCALE48RMZE)

SCALE48RM specifications + Robot Z-axis extension

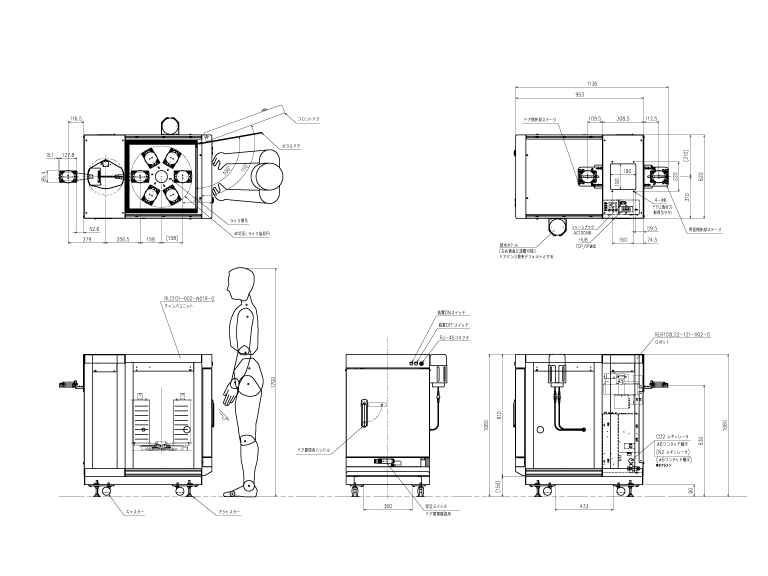

Product dimensions (Standard model)

Documentations

Various customizations are available

For inquiry on this product, please click

on this link

SMART LAB SCHEDULING PACKAGE

Product Features

AsuRa® is a comprehensive scheduling software package for bio-automation that is newly developed to strongly support the cell culture technology that gives life to cells, which is the basis of life science.

Unitary management and automation for all related to cell culture

Cultivation of cells including iPS cells requires the complex setting and management of conditions for all process such as seeding, culturing, medium exchange, monitoring, and collection. It is also necessary to supply and dispose of consumables and culture media (reagents), and to manage input information and output data as well. In order to fully automate them (unmanned), flexible and powerful comprehensive scheduling software together with systemized hardware (combination of devices) is indispensable. It has been considered impossible for the conventional scheduling software. However, AsuRa® can automatically manage the conditions and progress of series of cell culture for every plate(dish) and complete fully automated culture plan by totally controlling robots, transferring devices, incubators, dispensers, detectors, consumables, reagent supply and disposal devices, etc., which comprise automated system, according to parameters and protocols (schedules) set by the user.

Furthermore, data such as cell information, culture conditions, work / monitoring / detection results are stored and managed. In addition, it is also one of other major features that the culture plans can be interactively added and changed interactively at any time without stopping the ongoing culture plan.

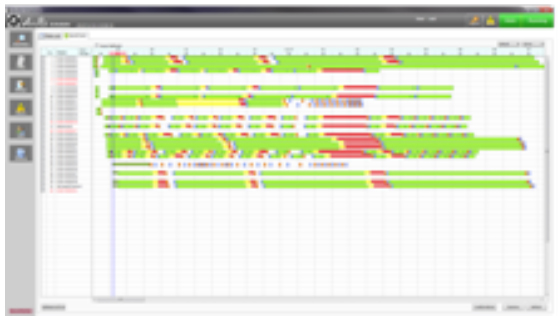

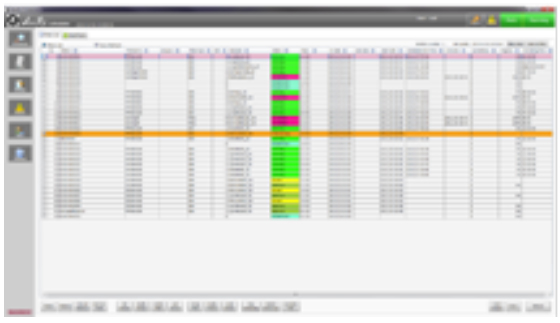

Example for software screen

Overview screen

Scheduling table(Gantt chart)

Plate control screen

Recipe control screen

For inquiry on this product, please click

on this link